The term clamps covers a lot of territory. Some specialty clamps have very specific applications in the workshop, making them even more valuable to any woodworker.

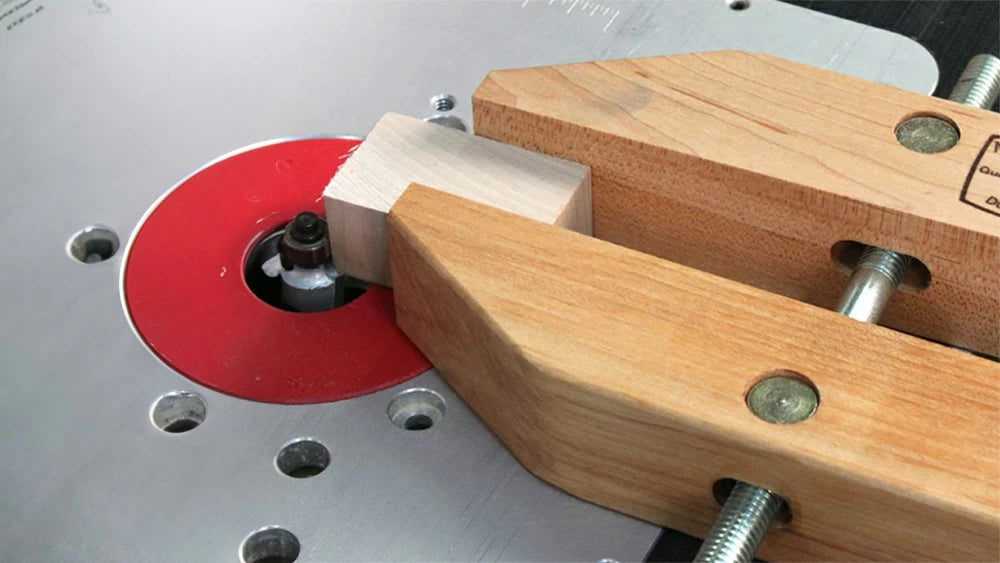

Hand Screw Clamps

First up is the venerable Hand screw clamp. Possibly the oldest clamps on the planet, clamps with wooden screws can still found in flea markets throughout the US. But the steel screw clamps date back to 1903. Available in a wide variety of sizes, hand screw clamps provide positive pressure along the length and face of the clamp, on both sides. Excellent for aligning boards for a glue-up, or easily used as a stop on a fence.

They also add a level of security when working with small pieces near cutting tools, and can add an extra hand when supporting longer workpieces. In general, hand screw clamps are as versatile as your imagination, and a great addition to any modern shop.

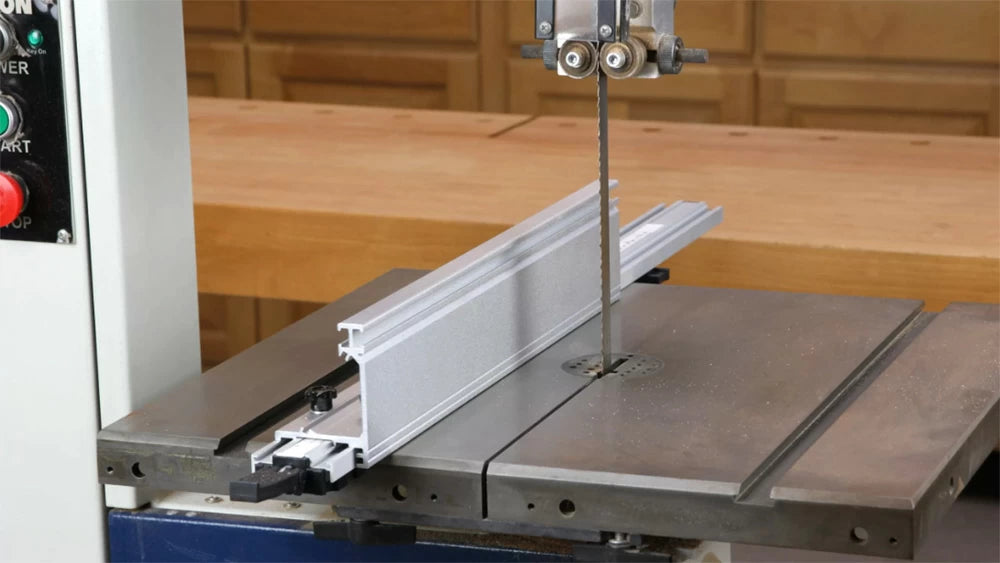

Straight Edge Clamps

You may not think of a straight edge as a clamp, but that’s what it is. Available in a variety of lengths, the mechanism underneath clamps across a workpiece with enough force to hold the aluminum straight edge in place. Perhaps not enough clamping pressure for a glue-up, but excellent for guiding circular saws, jigsaws, router and much more.

And the T-track extrusions along the top edge allow for the addition of other shop helpers such as a fence for your bandsaw.

Band Clamps

When it comes to clamping odd shapes, there’s one reliable answer: A band clamp. The 23-foot adjustable band is tightened with great pressure in a large circle. Corner blocks can be used to tighten against corners … or the band itself can brace against rounded corners or even cylindrical objects. You’ll know when you need a band clamp.

Toggle Clamps

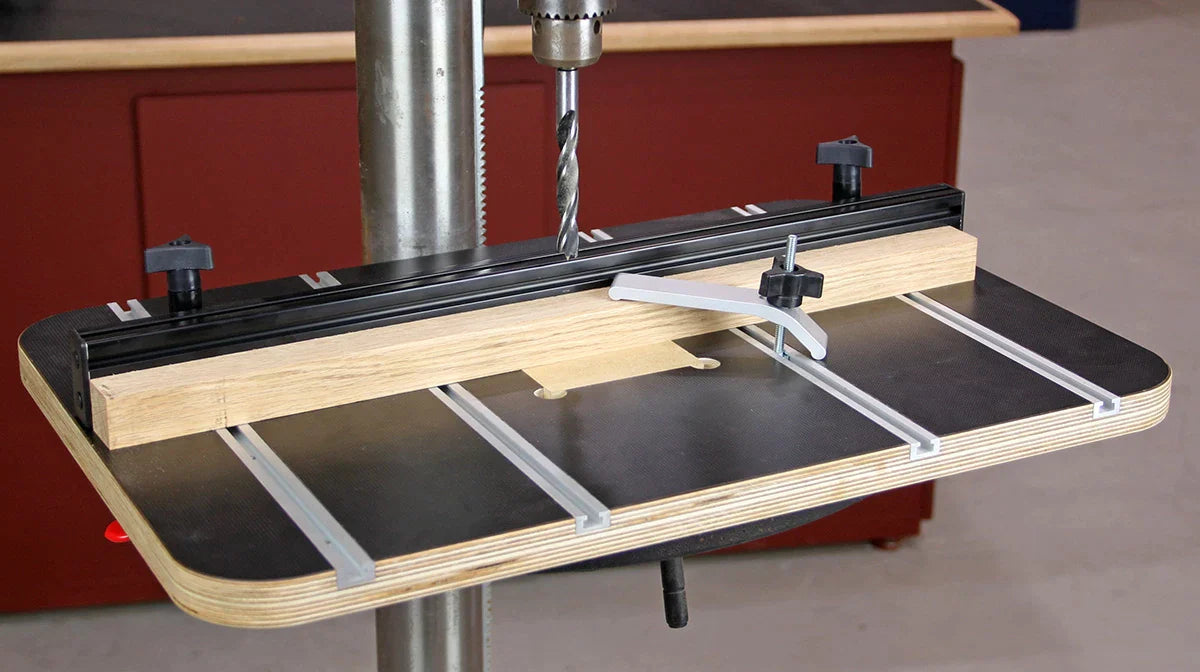

Another specialty clamp is a toggle clamp. These are integral in jigs and fixtures throughout a workshop and are available in a variety of sizes, shapes and mountings. There are even self-adjusting toggle clamps to get the best pressure without a lot of fiddling around.

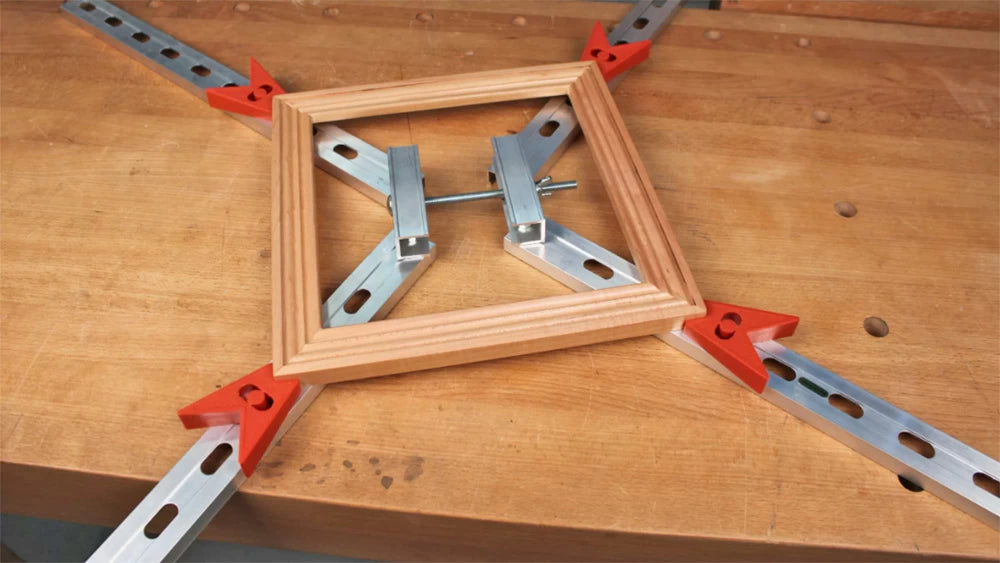

Frame Clamps

And last on our list is a very specialized clamp. An adjustable frame clamp provides even pressure on the four corners of any frame. As an extra benefit, the contact on the frame is so slight that you can reach in to pin a corner without fuss.

Make sure your shop has all the specialty clamps you’ll need for your special project.