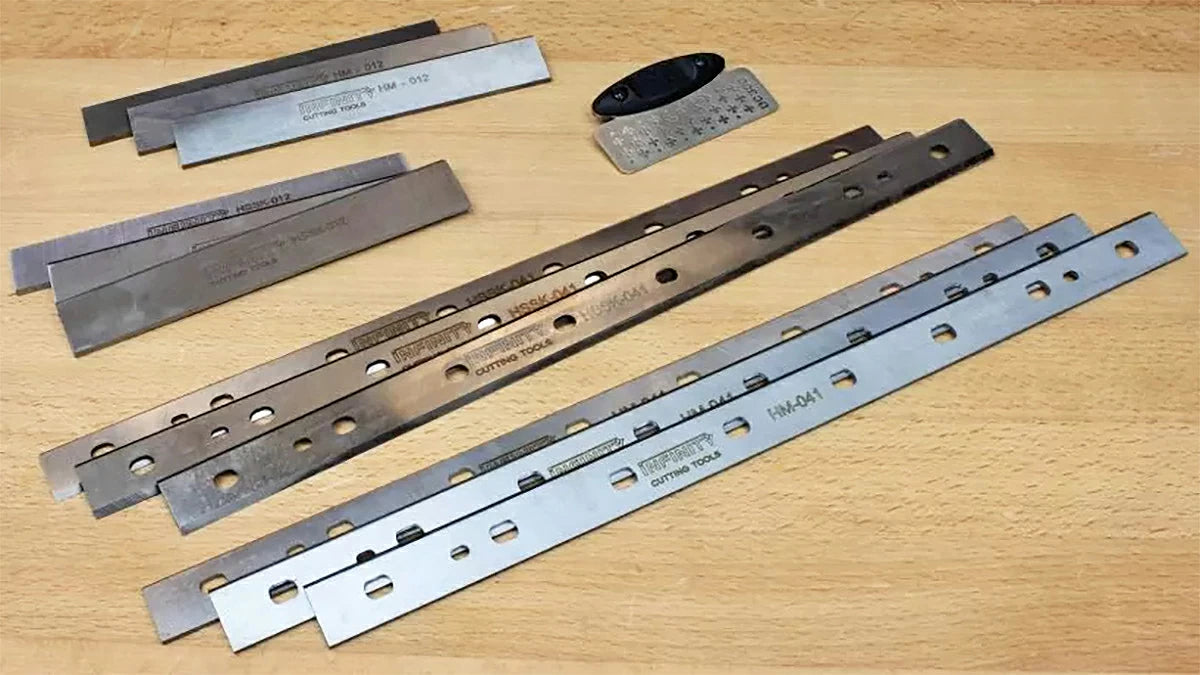

We all know that just about any cutting tool you buy needs to be sharpened or honed before use. This is true with hand tools like chisels and plane irons, kitchen knives, and even jointer and planer knives. Most manufacturers state that their knives come sharp and are ready to use right out of the box and technically that's true. The knives have been sharpened at the factory and if you throw them in your machine they will work. But a little honing can bring a set of knives to the next level and extend their life and improve cut quality.

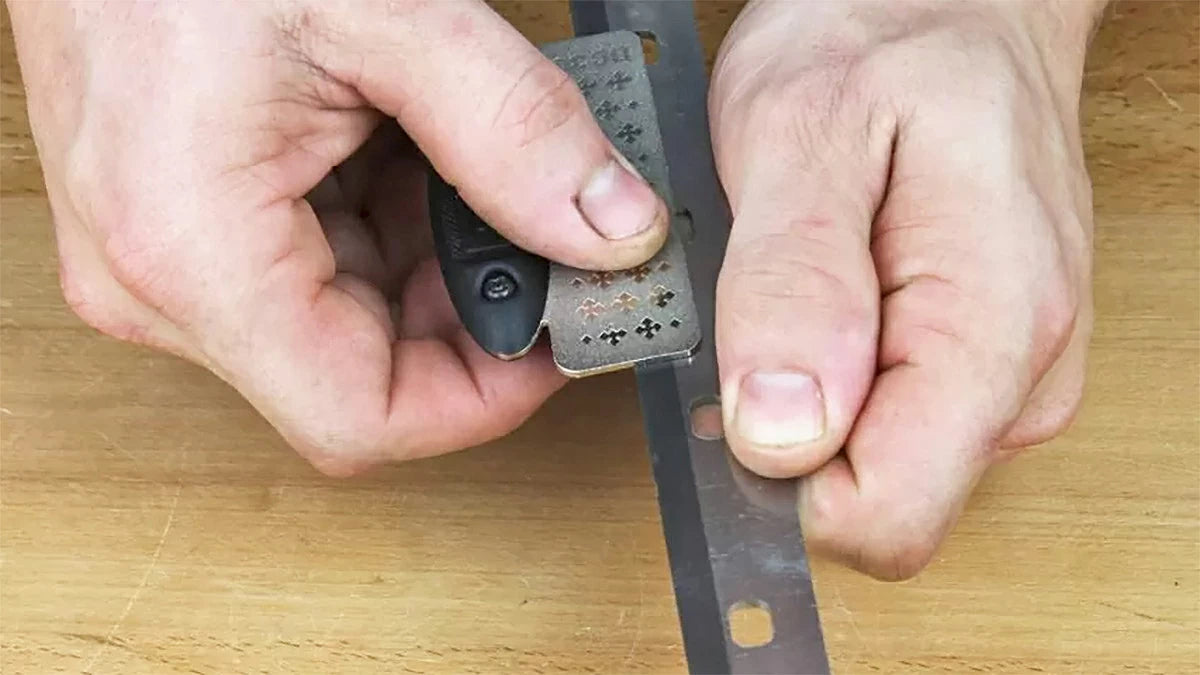

Sharpening a set of knives is not a difficult task. High speed steel (HSS) and carbide-tipped knives can be sharpened with a diamond sharpener like the M-Power model shown below. The goal here is simply to make a few strokes down the bevel of the knife and a few strokes down the back. This removes any burr that is left from the factory grinding process and refines the edge to be sharper and longer-lasting.

Remember, all it takes is a few light strokes with a fine diamond hone on both the bevel and back of the knife. We're simply refining the edge — not grinding a new one. There's a law of diminishing returns when it comes to sharpening HSS or carbide jointer and planer knives. Sharpening these materials to a razor-sharp edge in reality is not worth the effort. While you can most likely sharpen a HSS knife to be sharp enough to shave with, the first board through the planer will take that edge away. We recommend sharpening to roughly 600 grit. Any finer and the resulting edge gained will only last a short time.

Carbide-tipped router bits and saw blades have made their steel counterparts a thing of the past. Carbide has about ten times the wear-resistance of steel plus, the benefits of a carbide planer knife are the same as these other cutting tools. While the carbide edge won't initially feel or be as sharp as a honed HSS knife the edge the carbide does have will last many times longer. The same honing process is used with carbide knives and can bring a factory-sharp or used carbide edge up to its full potential.

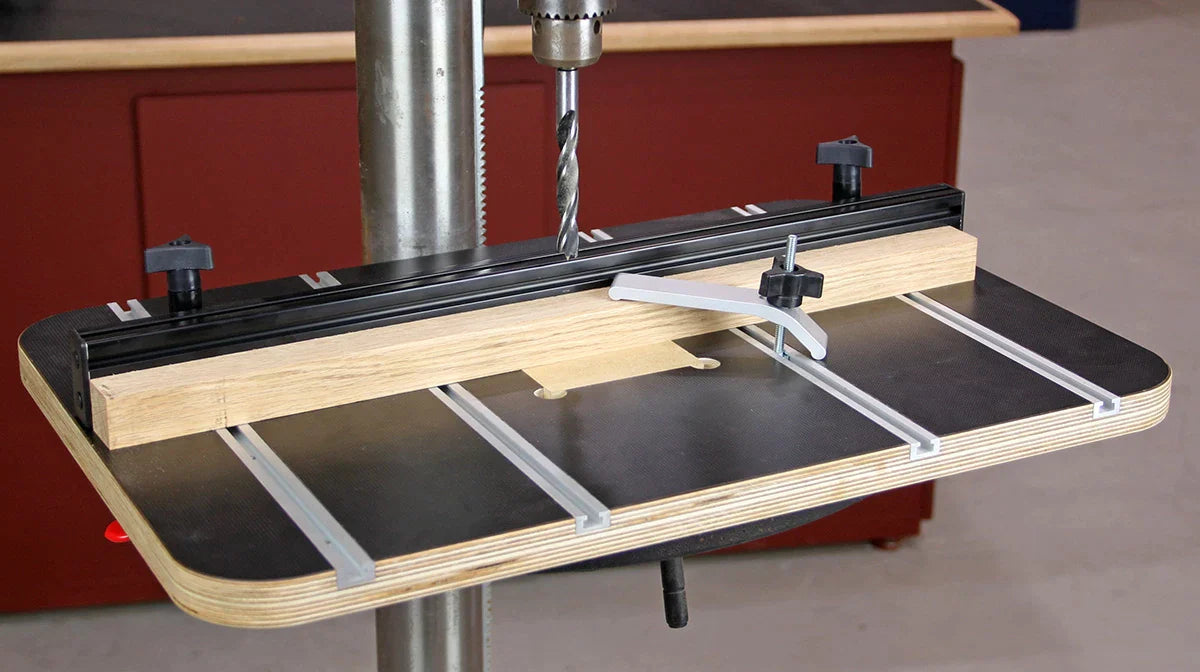

Taking a few minutes to refine the factory edge on your new Infinity planer or joiner knives is a great way to get the most out of your knives. We also recommend periodically refreshing your knives by cleaning and buildup from the knives and honing them with your diamond hone. For machines with a traditional cutter head a Diamond Knife Hone can allow you to hone your knives without removing them from the machine, but for most machines with indexed knives like the DeWalt 734 or 735 you will need to remove the knives for sharpening. Also on any indexed knife it is important to remove as little material as possible. Because the knives cannot be adjusted in the machine removing too much material from the cutting edge will shorten the knife and it will no longer reach the workpiece. This will cause the machine to not feed properly or cause other parts of the cutterhead to contact the workpiece and can cause serious damage to the planer.

The moral of the story is just like any other machine in your shop — it's important to show your joiner and planer knives a little love from time to time and keep them clean and sharp. To clean them, we recommend Blade & Bit Cleaner. To hone non-indexed knives on jointers and planers with traditional-style cutterheads, check out the Diamond Knife Hone. This tool allows you to hone the knives while still mounted in the cutterhead. With just a little effort, your old knives work like new and your new knives work better than new.

For a more detailed look at maintaining jointer and planer knives, check out this blog post and video.